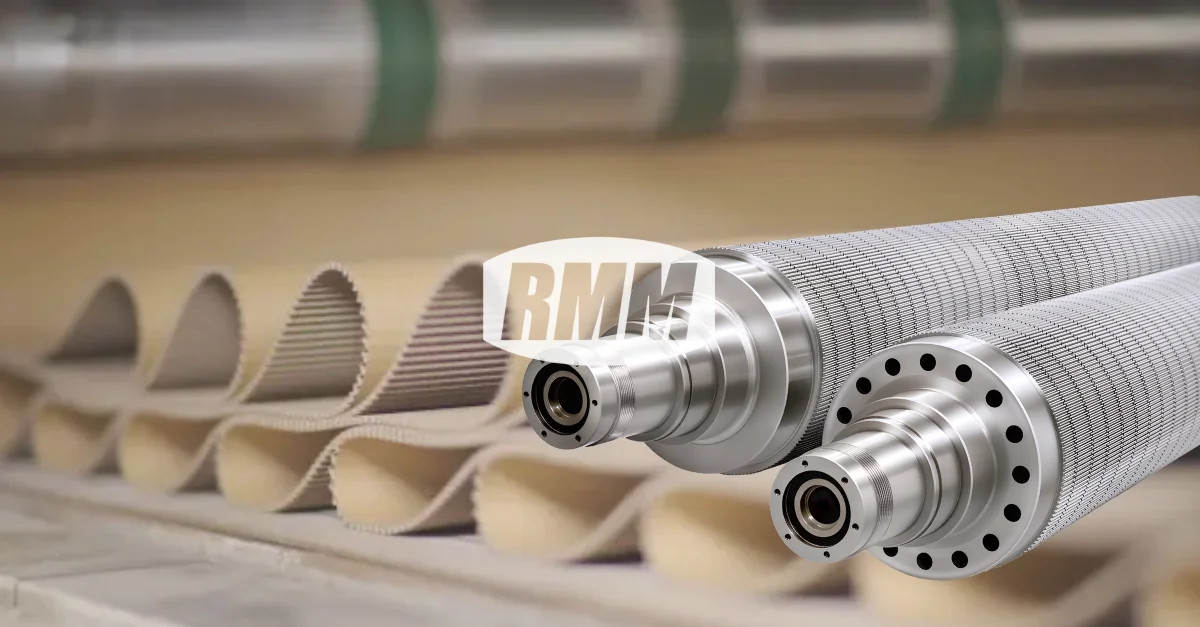

In an era of complex supply chains and rising logistics costs, choosing the right packaging is more critical than ever. Corrugated cardboard remains the material of choice for its versatility, sustainability, and strength. But how can you be sure your boxes will protect your products from the warehouse to the customer’s door? The answer lies in understanding key performance tests. At RMM, we believe reliable packaging begins with measurable strength. This guide breaks down the four essential metrics—ECT, FCT, BCT, and TUR—that define the quality and durability of corrugated packaging.

1. Edge Crush Test (ECT): The Measure of Stacking Strength

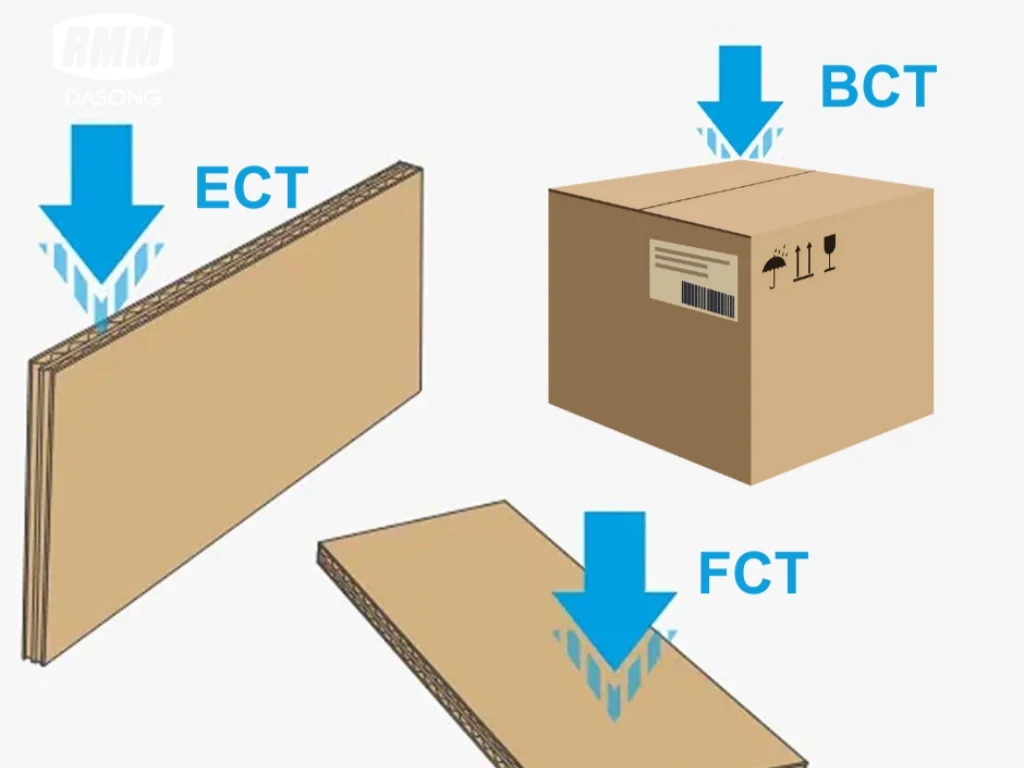

- What It Is: The Edge Crush Test measures the compressive strength of the corrugated board itself, specifically its resistance to force applied to its edge.

- Why It Matters: ECT is a direct indicator of a box’s ability to withstand stacking in a warehouse or during transportation. It answers the fundamental question: ‘How much weight can this box support from above?’

2. Flat Crush Test (FCT): Assessing the Flute’s Protective Power

- What It Is: The Flat Crush Test evaluates the resistance of the flutes (the middle layer) to a force applied perpendicularly to the face of the board.

- Why It Matters: While ECT tests vertical strength, FCT evaluates the board’s rigidity and ability to protect against impacts, punctures, and crushing during handling. It ensures the flutes maintain their structure to provide cushioning.

3. Box Compression Test (BCT): Validating Overall Box Performance

- What It Is: The Box Compression Test measures the maximum compressive strength of a fully assembled, sealed box until it deforms.

- Why It Matters: BCT moves beyond material testing to evaluate the finished product’s performance. It simulates real-world stacking conditions in shipping and storage, accounting for factors like box design, seals, and overall construction.

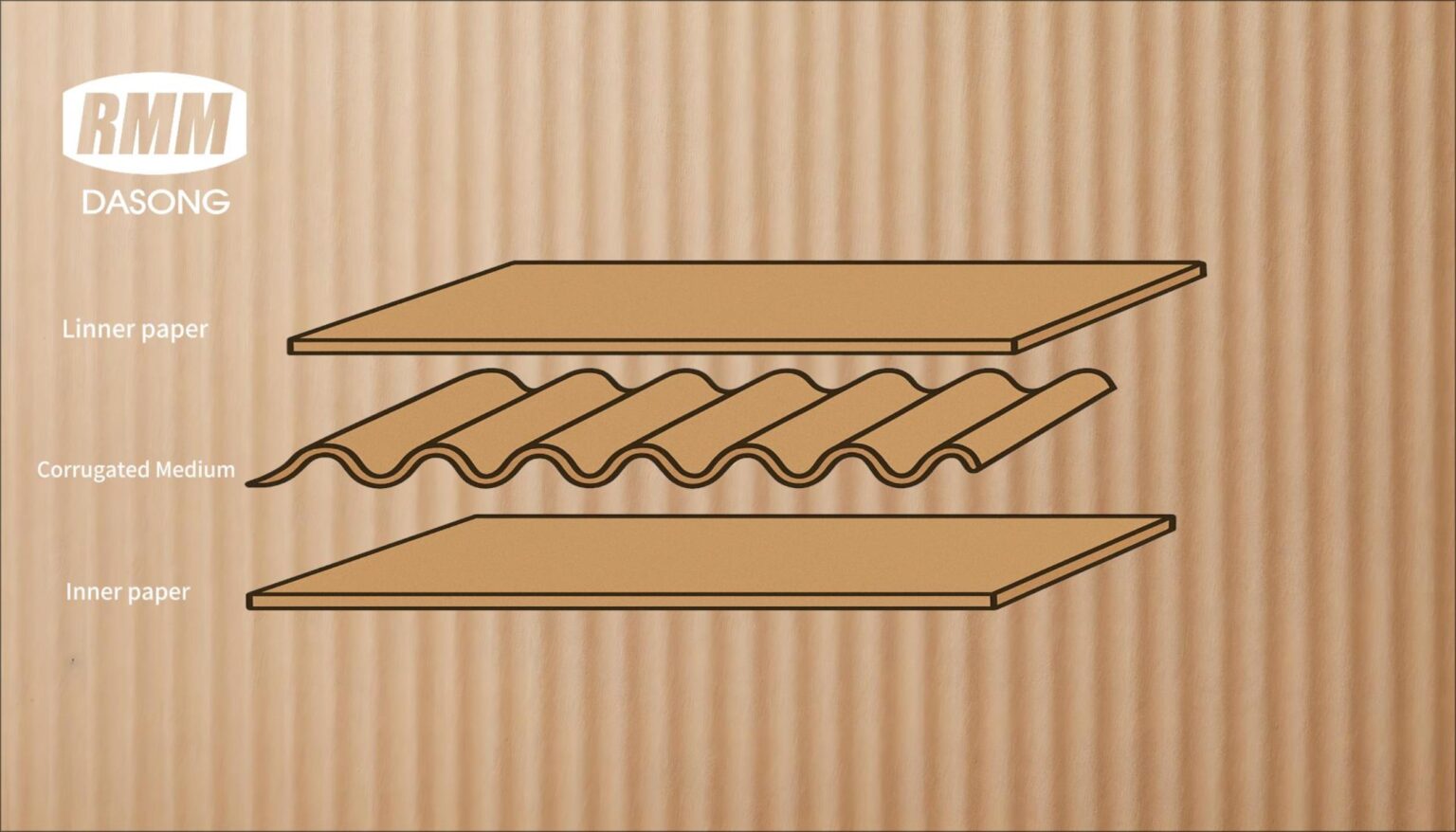

4. Take-Up Ratio (TUR): The Blueprint for Flute Efficiency

- What It Is: The Take-Up Ratio is a geometric calculation, not a strength test. It represents the ratio of the length of the corrugated medium to the length of the linerboard it is glued to.

- Why It Matters: TUR defines the flute profile’s efficiency. It determines the cardboard’s thickness, cushioning ability, and material usage. Think of it as the “architectural plan” for the corrugated structure.

- Business Implication: TUR helps in selecting the right flute type (e.g., A, B, C, E) for your application. A higher TUR is chosen for superior protection, while a lower TUR offers a flatter surface for high-quality printing and a more rigid box.

Choosing the Right Cardboard: A Quick Guide

Selecting the correct corrugated specification is a strategic decision that impacts cost, protection, and efficiency.

| Application | Key indicators | What to prioritize |

| Heavy, stackable goods | ECT & BCT | High stacking strength and structural integrity |

| Fragile or delicate items | FCT | Strong flute protection and cushioning |

| Cost-sensitive or lightweight packaging | TUR | Balanced flute design for efficiency and printability |

The strength of corrugated cardboard is not a mystery. By leveraging the scientific data provided by ECT, FCT, BCT, and TUR, businesses can make informed, strategic packaging decisions. Understanding these metrics allows you to optimize for protection, reduce shipping damages, control material costs, and enhance your supply chain’s reliability.

At RMM, we go beyond standard solutions. We specialize in engineering custom flute profiles tailored to your unique product needs. Whether your priority is maximizing ECT, achieving a specific BCT, or optimizing FCT for superior cushioning, RMM can design the perfect corrugated structure for you.