Regular maintenance is essential to ensure the stable performance of corrugating rolls and to extend their service life. Proper care not only protects the roll surface and critical components but also guarantees consistent board quality throughout production. Below are the key maintenance practices recommended for corrugated roll users.

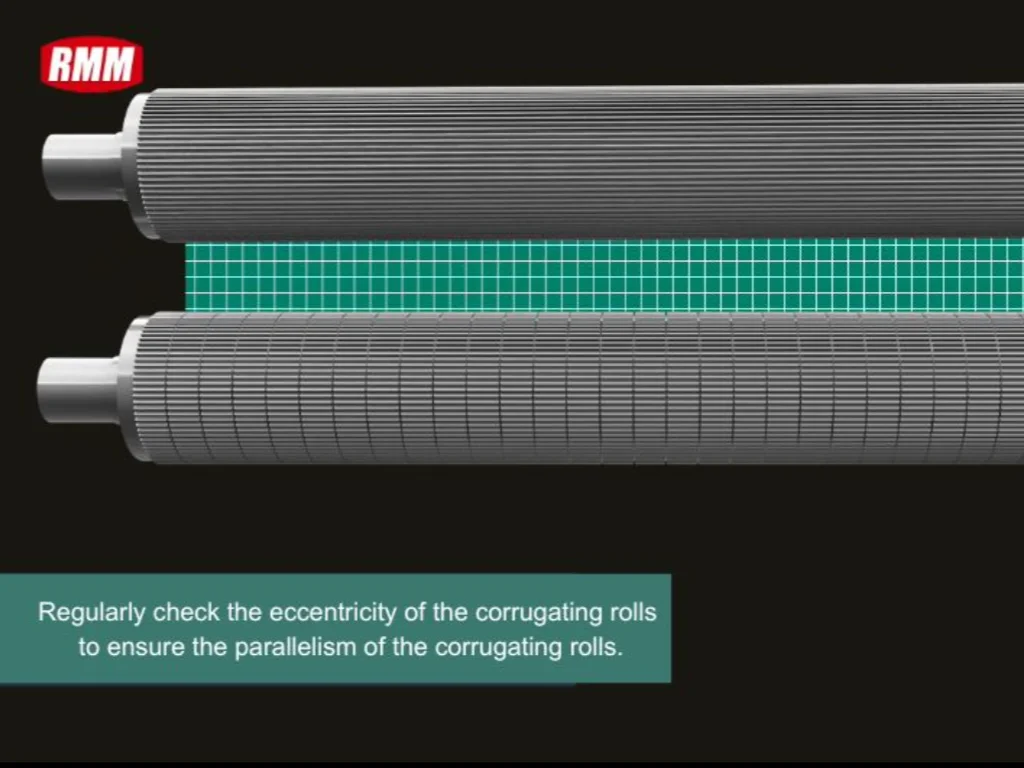

1. Regularly Align and Adjust to Ensure Corrugated Rolls Are Parallel

If the corrugated rolls are not kept parallel, it will not only affect their lifespan but also the quality of the corrugated board. It is recommended to regularly check the parallelism of the corrugating rolls with carbon paper every week; if there is any deviation, it can be adjusted by the eccentric pin of the upper roll.

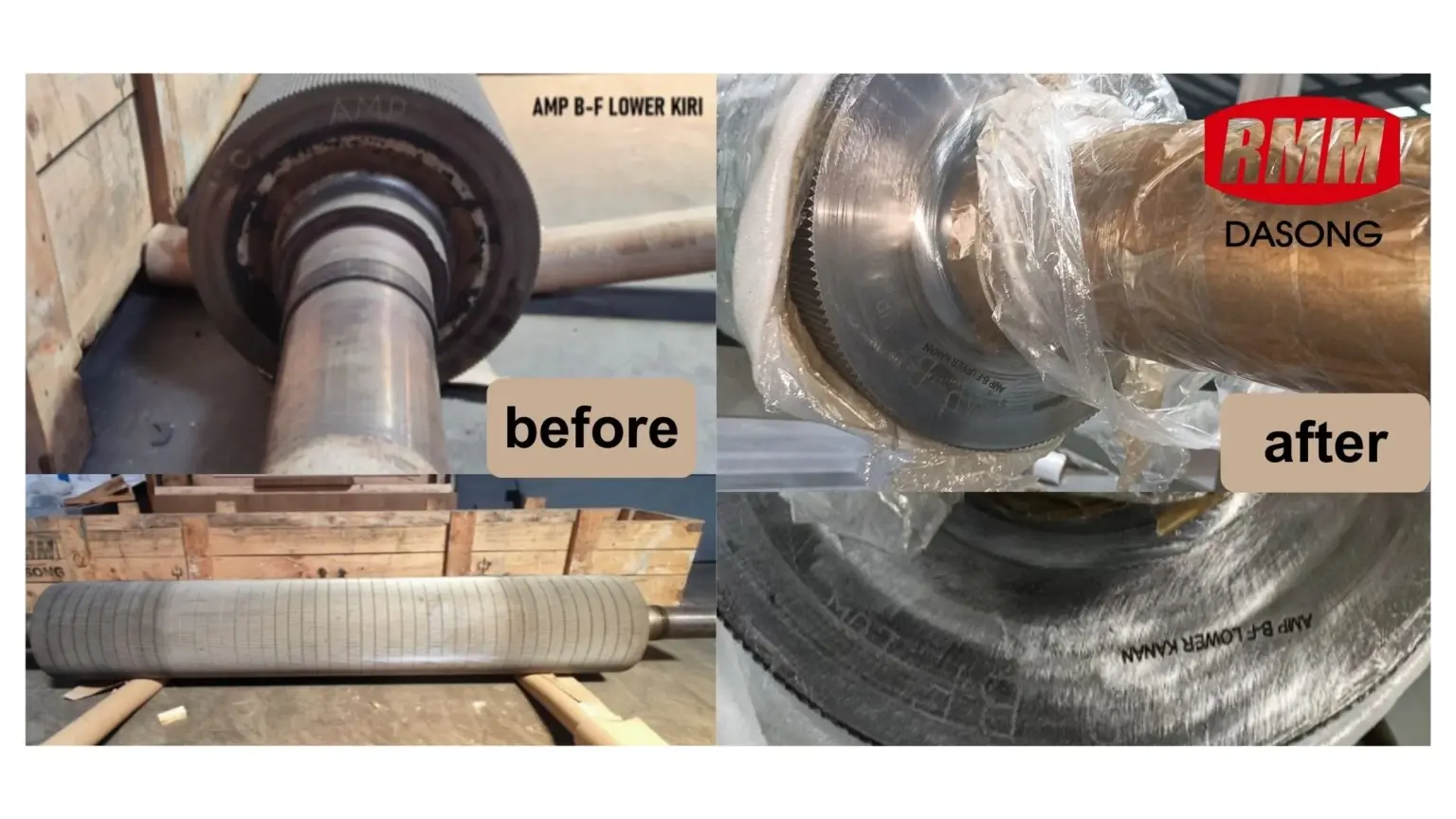

2. Regular Cleaning to Extend Corrugated Roll Lifespan

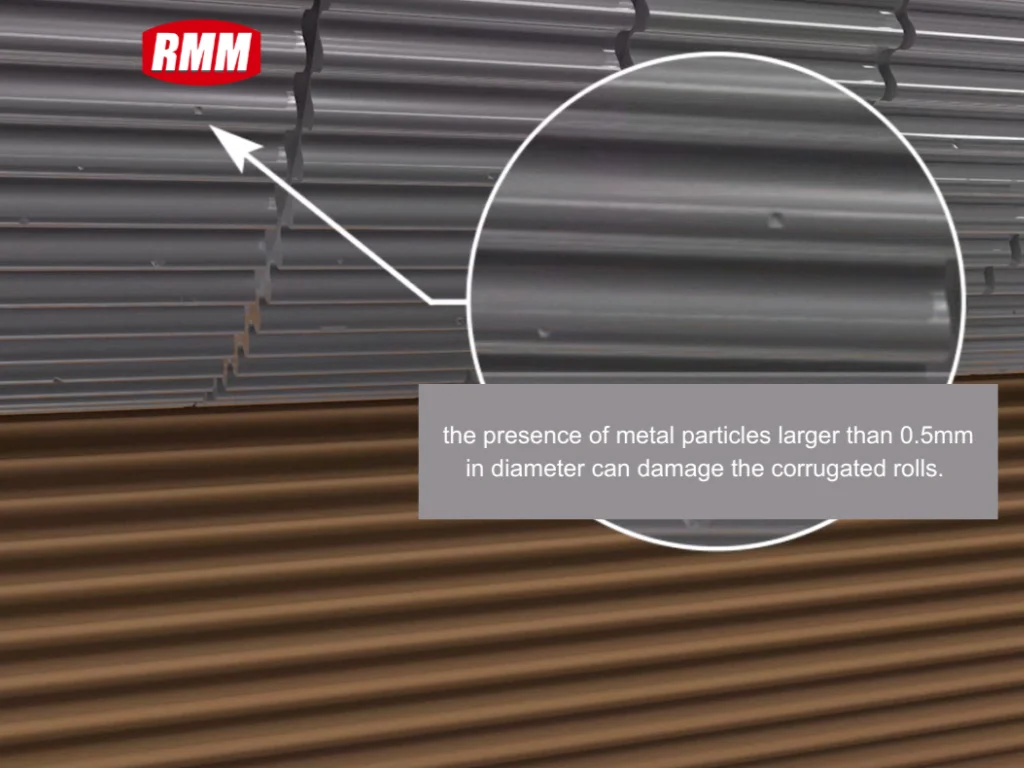

Wear on the corrugated rolls can be reduced by removing paper scraps, carbonized adhesive, and other contaminants. Experience shows that the presence of metal particles larger than 0.5mm in diameter can damage the corrugating rolls.The corrugated rolls and single facer should be kept sufficiently clean to avoid unnecessary transmission of large particles between the rolls. for the internal suction type corrugating rolls, it is necessary to inspect and clean the suction holes twice a week, and the suction device should be disassembled and cleaned once every half a month.

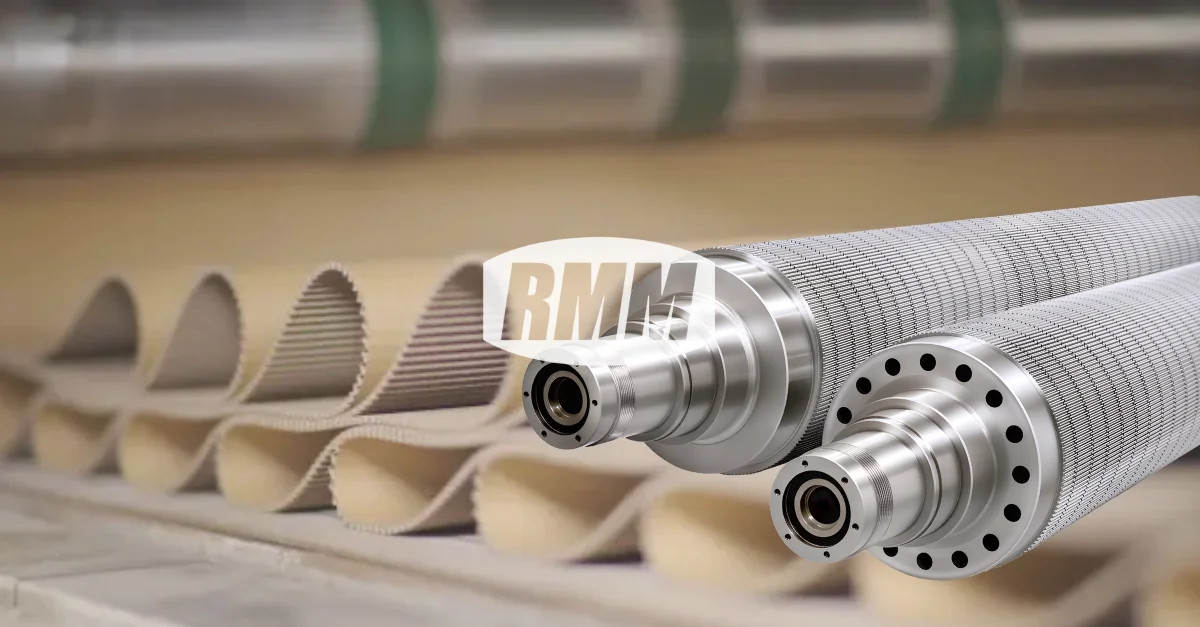

3.Lubrication

The lubrication system should be disassembled monthly to ensure proper flow of lubricating oil and proper lubrication of the bearings. Otherwise, worn bearings will cause vibration, shorten the lifespan of the corrugated rolls, wear down the corrugated board, and reduce the quality of the corrugated board. Check the lubrication points of each bearing every half a month, and add high-temperature resistant grease in time if the oil volume is insufficient.

To make the corrugated board production line run efficiently, daily maintenance is indispensable. The daily maintenance of corrugating rolls can greatly extend their service life, improve production efficiency, and reduce replacement costs. Therefore, it is necessary to do a good job in the daily maintenance of corrugating rolls and protect the “heart” of the single facer.