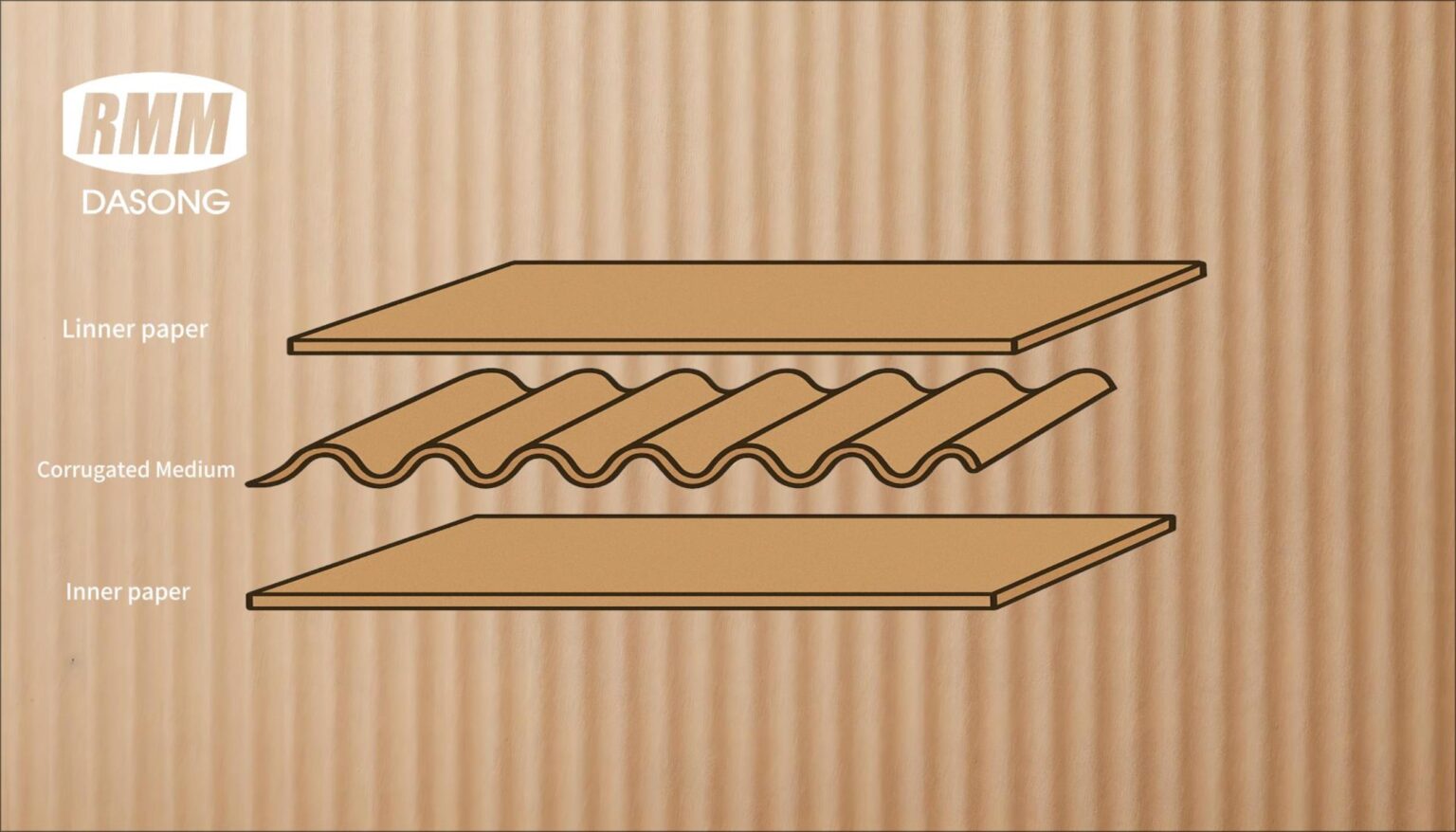

During the production of corrugated board, flute crushing is a common issue. Once the flutes are flattened, the board’s compression strength is significantly reduced, directly affecting the box’s stacking and load-bearing performance. The causes of flute crushing vary, and the main issues and solutions are summarized below.

Main Causes & Solutions

1.Corrugating rolls are not parallel (flute tilt)

Solution: Adjust the corrugating rolls to ensure full parallel alignment.

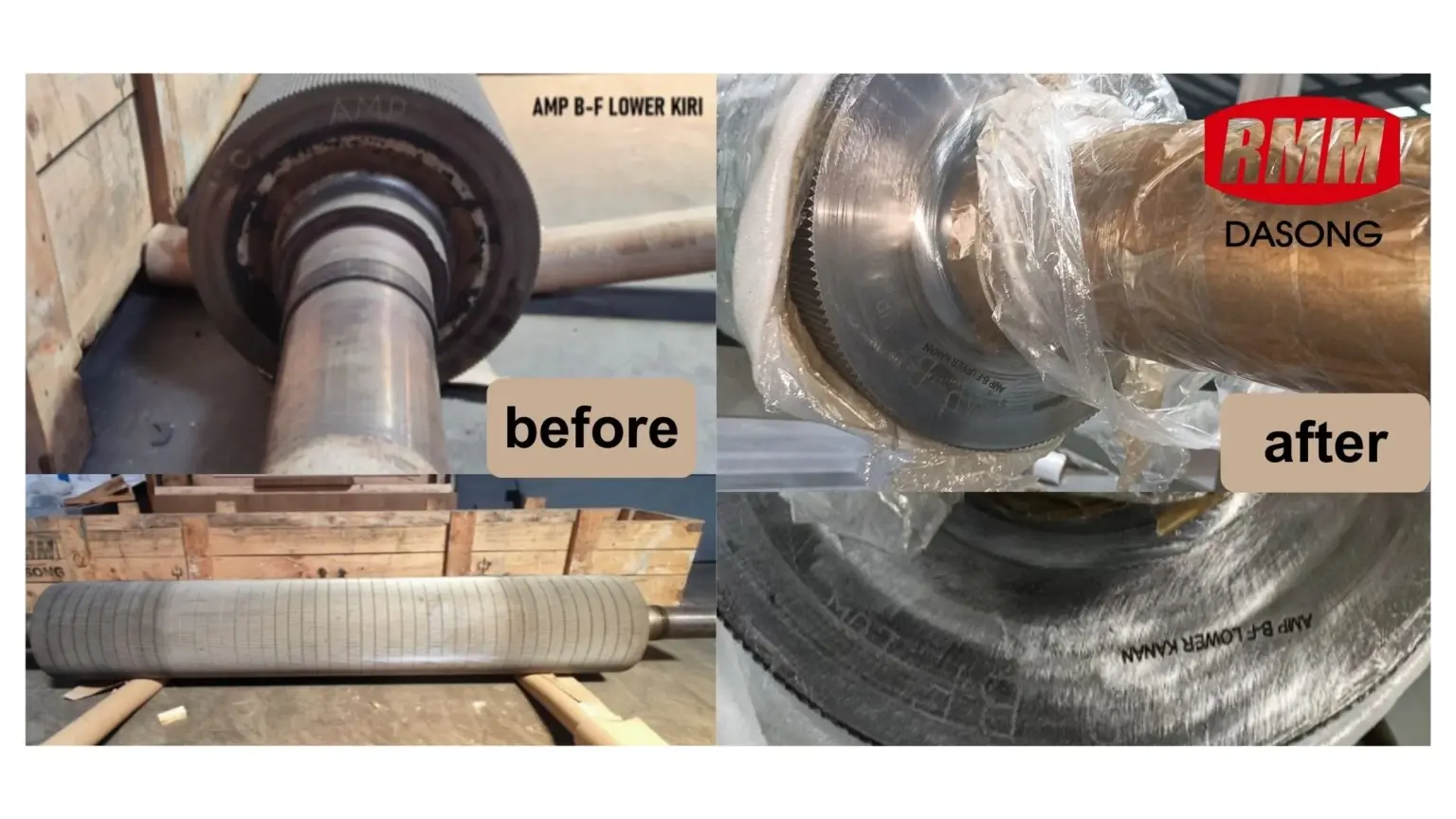

2.Low flute height at the start or worn corrugating rolls

Solution: Replace the corrugating rolls.

3.Flutes are crushed after forming

Solution: Inspect and correct all nip points or contact points that may crush the flutes.

4.Excessive tension on the medium paper roll

Solution: Reduce the brake force on the paper stand; check the preconditioner position; dry, repair, or replace the preconditioner’s drive motor.

5.Too much steam from the spray system, causing over-moistening

Solution: Reduce the amount of steam applied to the medium.

6.Glue unit crushing the flutes at any nip point

Solution: Reduce glue application while maintaining good bonding and preventing warping; if medium moisture is too high, reduce steam, shut off spray systems, or replace the medium paper roll.

7.Uneven tension of the double-facer belt (diagonal flutes)

Solution: Keep the conveyor belt tension and running speed consistent.

8.Low compression strength of the medium paper

Solution: Replace the medium paper roll and consult with the paper supplier.