In most corrugated board plants, corrugating rolls are inspected and adjusted on a regular basis. Key inspection parameters include flute pitch, flute height, roll crown, roll diameter, and roll meshing gap.

Once any of these parameters are improperly set, corrugating performance will be affected, which can eventually lead to an overall decline in corrugated board quality.

1. Excessive Flute Pitch

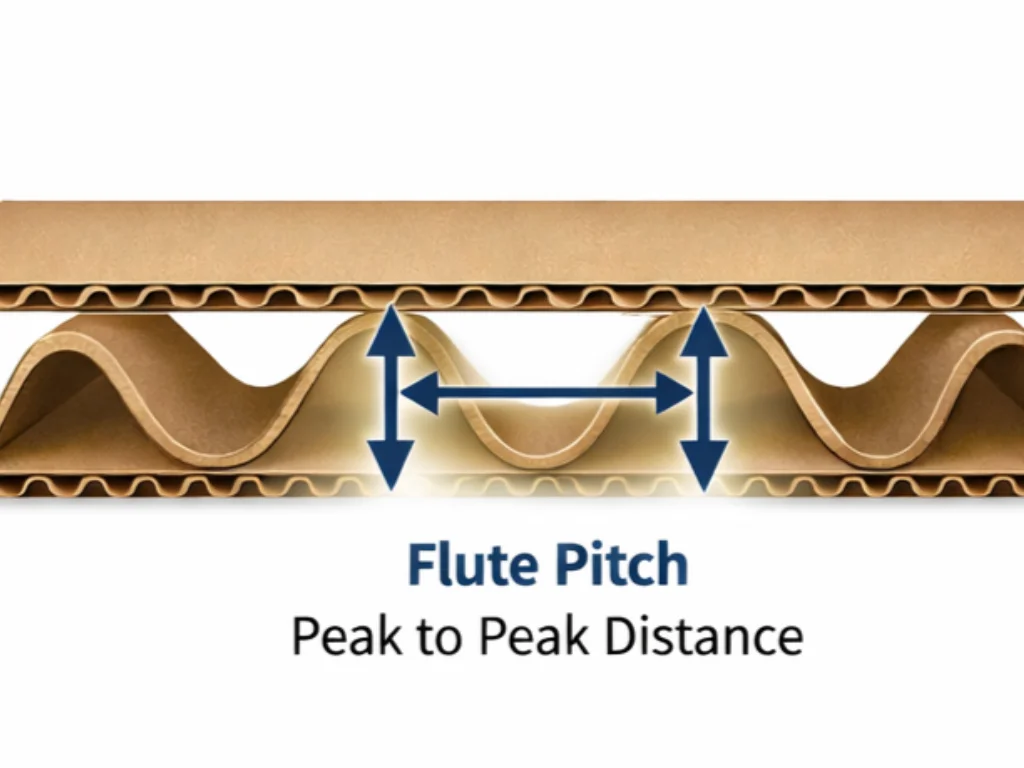

Flute pitch refers to the distance between two adjacent flute peaks and can also be expressed as the number of flutes per unit length.

Generally, a larger flute pitch means fewer flutes per unit length, which may reduce medium consumption and help lower material costs.

However, excessive flute pitch can cause several quality issues:

- Reduced flute support points, lowering overall board stability

- Negative impact on edge crush strength (ECT)

- Poor printability, leading to uneven printing pressure

Therefore, flute pitch should be properly controlled to balance strength, print quality, and material efficiency, rather than focusing solely on paper savings.

2. Excessive Flute Height

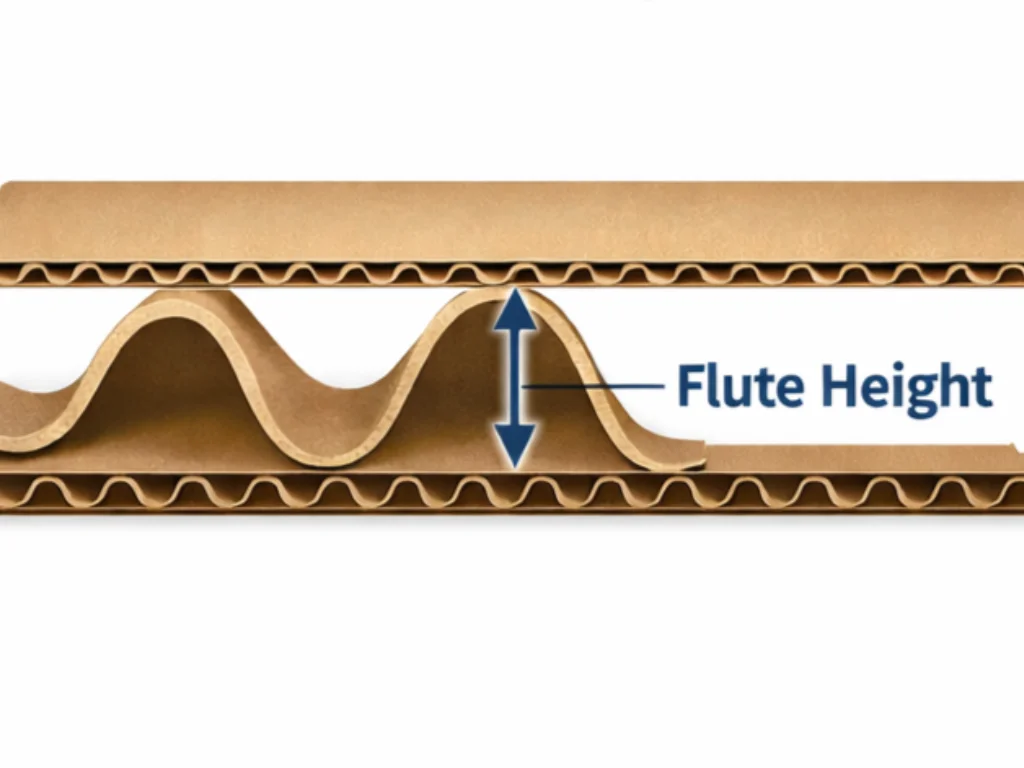

Flute height is the vertical distance between the flute peak and the flute valley, directly determining the thickness of the corrugated board.

In general, higher flute height increases board thickness and edge crush strength, but also raises medium consumption.

If the flute height is excessively high, it may result in:

- Reduced flat crush strength

- Increased load on flute tips, accelerating corrugating roll wear

- Lower forming stability and higher requirements for machine precision

Thus, flute height should be matched to the product structure and performance requirements instead of being increased blindly.

3. Improper Roll Crown

To ensure uniform and parallel pressure distribution on the medium and liner during operation, corrugating rolls—especially lower corrugating rolls—are usually designed with a certain crown.

Roll crown refers to the condition where the roll diameter at the center is slightly larger than at both ends, typically controlled within 18–50 microns.

The appropriate crown value depends on factors such as roll diameter, roll width, and material.

Some pressure rolls are designed with crown, while others are not, depending on the characteristics of the corrugator. Improper crown settings may lead to uneven pressure distribution and unstable flute formation.

4. Excessive Roll Diameter

A larger corrugating roll diameter offers higher rigidity, reduced vibration, and greater internal steam capacity, contributing to stable temperature control and easier operation.

However, excessive roll diameter also has drawbacks:

- Increased wrap angle and contact area with the medium

- Higher tension on the medium

- Potential forming instability under high-speed or lightweight paper conditions

Therefore, corrugating roll diameter should be selected based on machine design, paper grades, and operating speed, rather than simply pursuing larger diameters.

5. Improper Meshing Gap Between Corrugating Rolls

The meshing gap between upper and lower corrugating rolls plays a critical role in flute formation.

- If the gap is too small, the medium may crack or break, reducing flute strength

- If the gap is too large, roll resonance and vibration may increase, affecting forming stability

Only an appropriate meshing gap can ensure consistent flute quality and stable corrugator operation.

Conclusion

Proper inspection and control of corrugating roll parameters are essential for maintaining stable corrugated board quality and efficient production. Regular testing and timely adjustment of flute geometry, roll crown, diameter, and meshing gap help prevent quality fluctuations, reduce unnecessary wear, and improve overall production performance.

For corrugated board manufacturers, investing in precise corrugating roll inspection and optimization is not only a quality assurance measure, but also a key step toward long-term cost control and operational stability.