Corrugated board are widely used for packaging due to their strength and durability. The Edge Crush Test (ECT) measures their ability to resist edge compression, directly affecting performance during handling, transportation, and storage. ECT is closely linked to the Ring Crush Test (RCT) values of the linerboard and corrugating medium, and it can be influenced by multiple factors — including raw material quality, production process, board flatness, and storage conditions. Understanding these factors is essential to ensure consistent board strength and reliable packaging performance.

1.Raw Material Quality

The quality and moisture content of base paper are key factors affecting the edge crush strength of corrugated board. A lower ring crush strength of the raw materials—especially the corrugating medium—directly leads to lower edge crush strength. Meanwhile, excessive moisture significantly reduces compression strength; for every 1% increase in moisture, ECT may drop by 5–12%. Ideally, the paper moisture should be maintained between 8% and 12% to ensure proper bonding and stable board strength.

2. Corrugating Roll Process

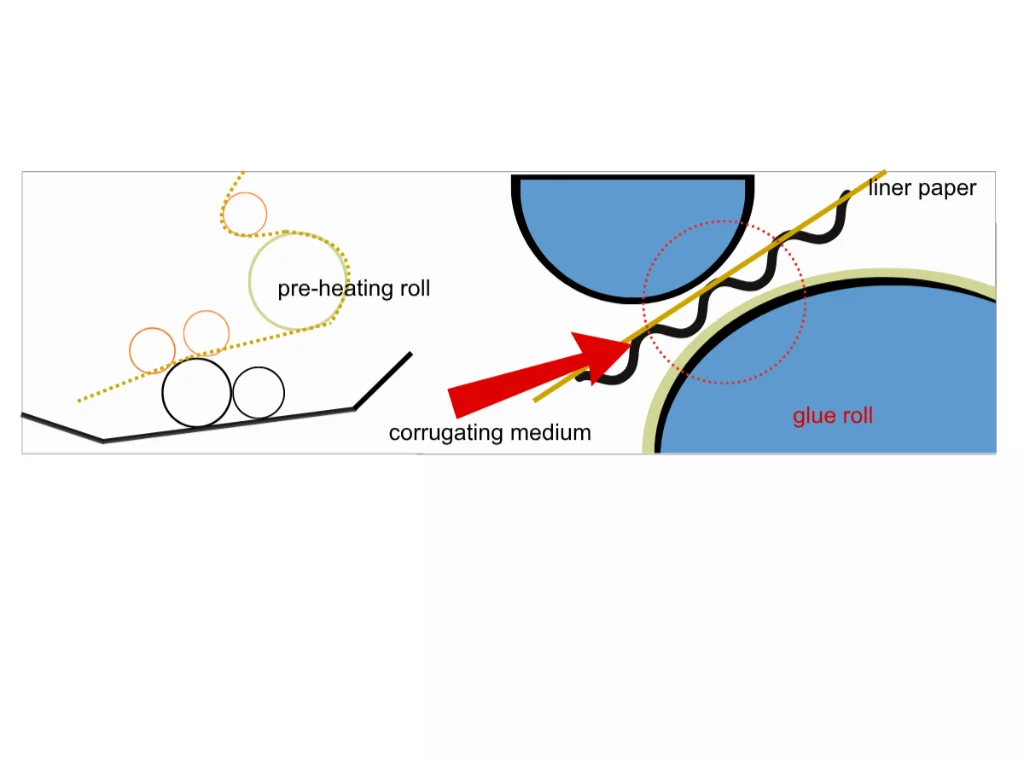

🔹Flute Forming Precision

Accurate flute forming is essential for load-bearing strength. When the corrugating rolls maintain proper flute height and stiffness without crushed or collapsed flutes, the resulting board structure can better resist edge compression. Any wear or damage to the rolls directly leads to weaker flutes and reduced ECT values.

🔹 Surface Condition & Adhesion

A clean and smooth roll surface ensures stable glue transfer and bonding between the medium and liner. Worn or contaminated flute tips disrupt adhesive distribution, lowering bonding strength and thus the board’s overall compression resistance.

🔹 Machine Alignment & Pressure Control

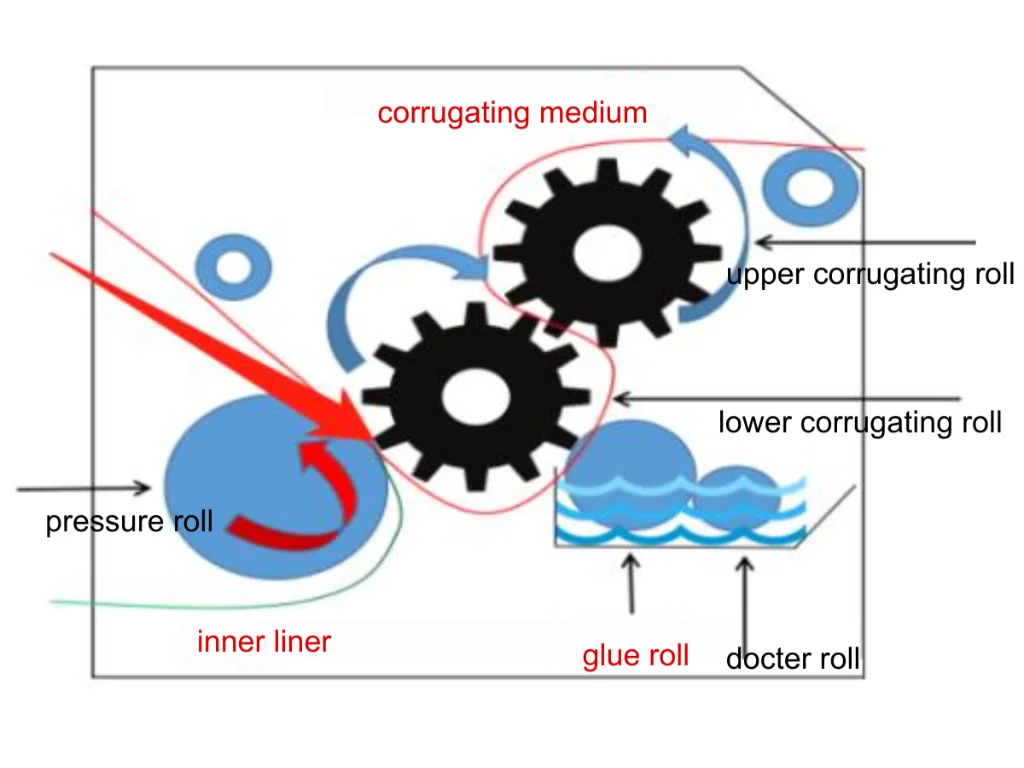

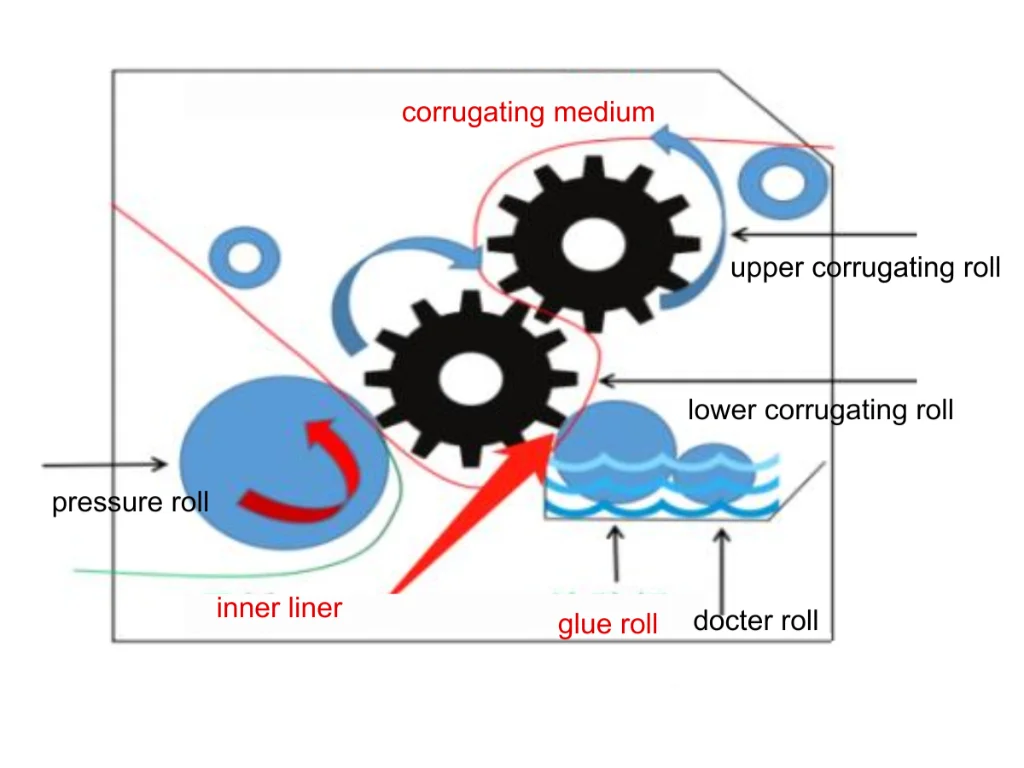

Proper alignment and pressure between the corrugating, pressure, and glue rolls are key to maintaining flute uniformity and bonding stability.

- Corrugating Roll & Pressure Roll: The gap between the pressure roller and the corrugated roller depends on the material. The general standard is that there should be no bubbling or black dent in the inner paper.

- Corrugating Roll & Glue Roll: The gap must be measured under heated conditions and typically set 0.02 mm larger than the flute medium thickness, ensuring parallelism across the roll width.

- Glue Roll & Pressure Roll (Double Facer Section): The gap between the glue roll and pressure roll should be 0.05 mm smaller than the corresponding board thickness, adjusted according to flute type.

3. Board Flatness

The flatness of corrugated board also affects its edge crush strength. During production, flatness should be strictly controlled. For every 1000 mm sheet of corrugated board, the warp should not exceed 20 mm. The maximum warp is measured by placing the board on a horizontal surface without any external load and recording the distance from the highest point of the board to the surface.

4.Storage Environment

Even corrugated board that meets ECT standards after production can experience changes in edge crush strength due to storage conditions. As environmental humidity rises, the moisture content of the stored board increases accordingly, which in turn reduces its edge crush strength.

In summary, the ECT strength of corrugated board is not determined by a single factor. It is systematically influenced by raw material quality, the precision of the corrugating process, board flatness, and storage conditions. A comprehensive understanding and control of this entire chain is essential for delivering packaging with reliable and consistent performance.