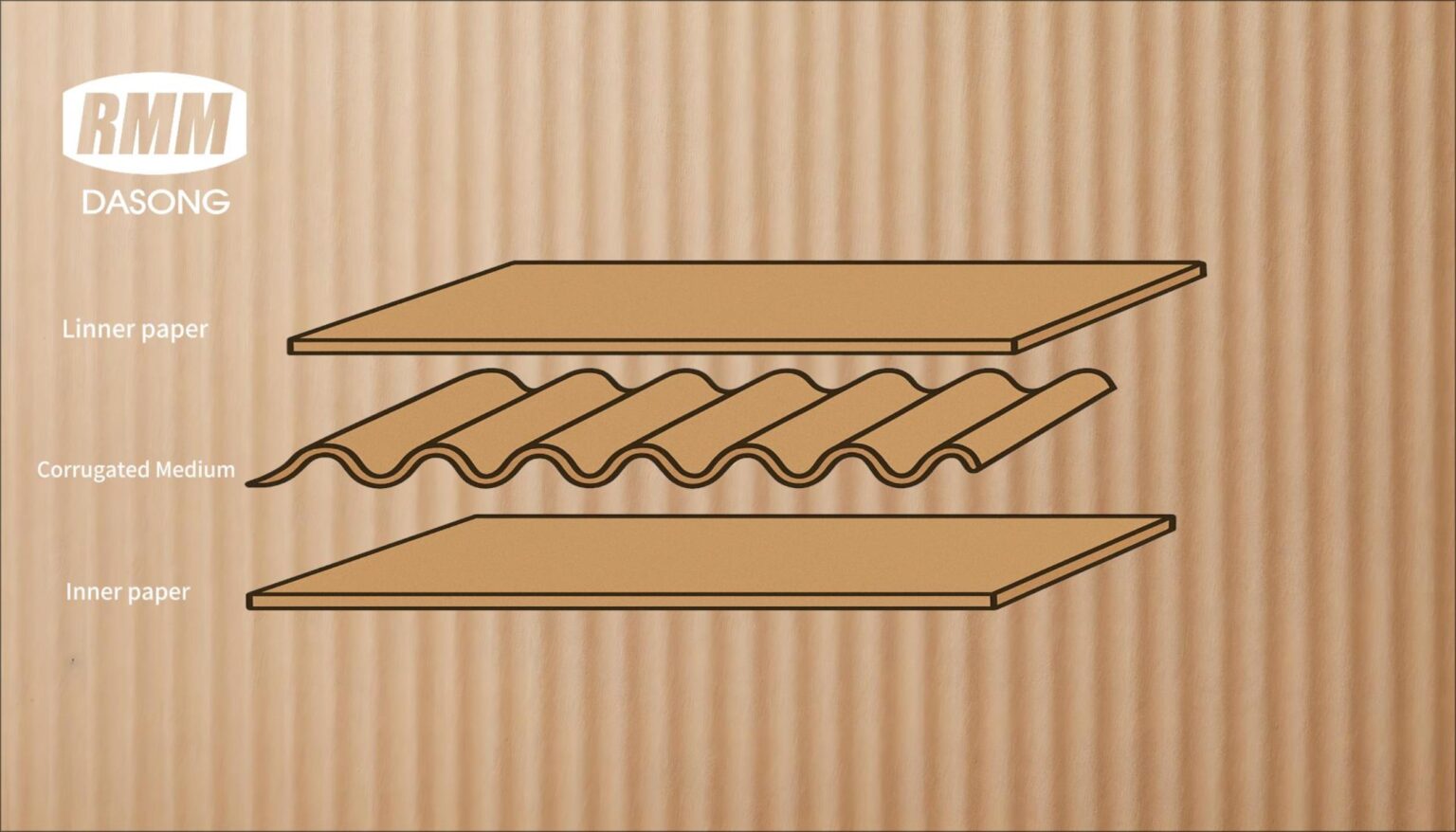

In corrugated board production, the condition of the corrugating rolls directly determines the forming quality, strength performance, and production stability. The following four aspects explain how corrugating rolls impact board quality.

1. Flute Profile and Dimensional Accuracy

Flute Height

Flute height affects board thickness and edge crush strength. Higher flute height usually leads to thicker board and stronger edge performance, but may reduce flat crush strength and accelerate roll wear. Uneven height or excessive wear results in inconsistent board thickness, affecting both strength and appearance.

Flute Pitch

This refers to the distance between two flute tips. Too large a pitch can affect printability and edge crush strength; too small increases paper usage and cost.

Take-up Factor

The ratio of the straightened length to the original length of the fluted paper. A higher factor uses more paper and may increase edge crush but can affect flat crush. Instability causes fluctuations in board performance.

2. Forming Quality

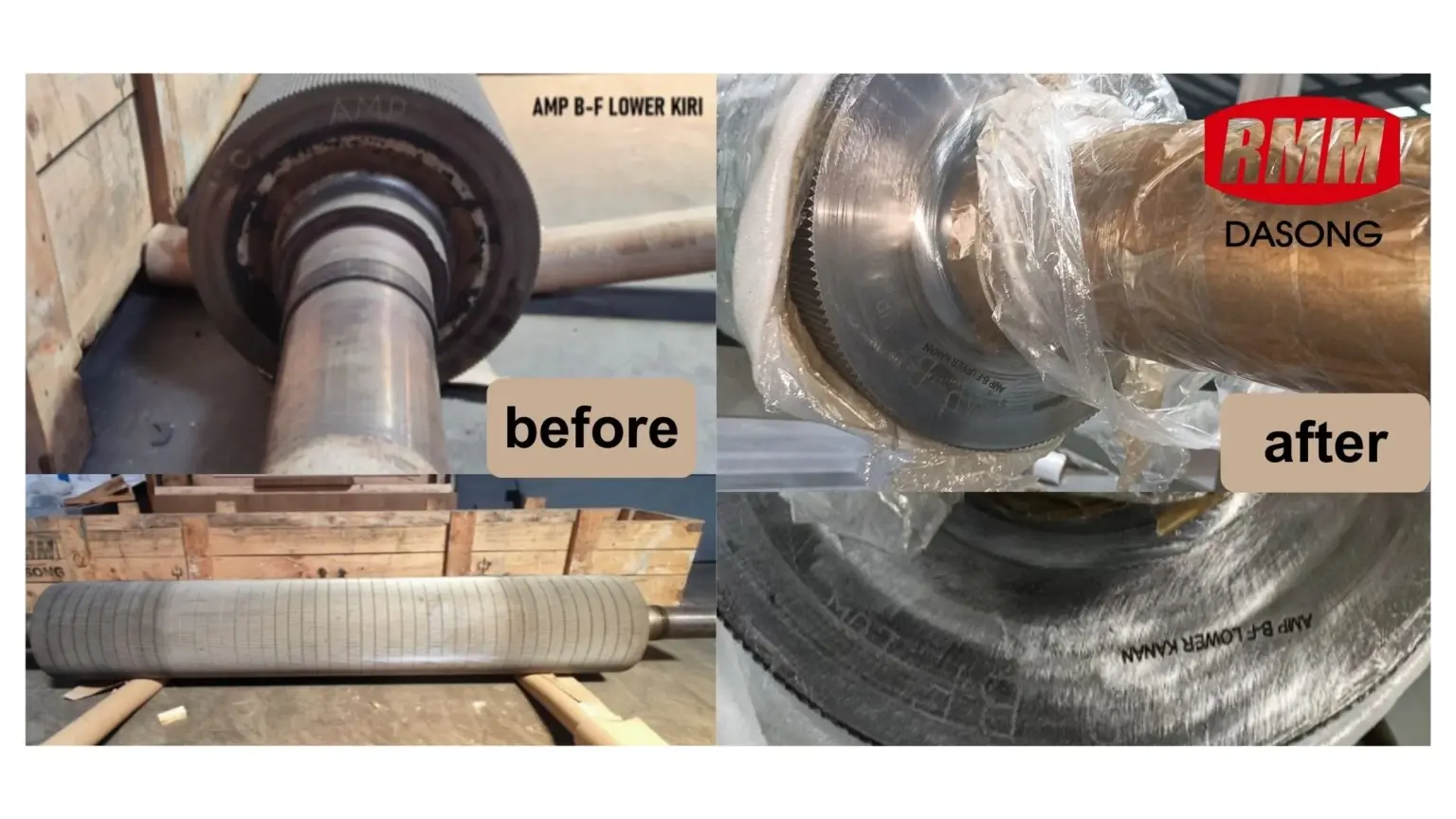

Tooth Profile Wear

Tooth wear on corrugating rolls leads to uneven flute forming, causing defects such as crushed flutes, collapsed flutes, and irregular heights. This affects board flatness and strength, and in severe cases may cause the medium paper to crack.

Nip Clearance

The clearance between the upper and lower corrugating rolls must be precisely controlled. If the gap is too small, the medium paper may break; if too large, it can cause vibration and unstable flute forming, resulting in skewed or overturned flutes.

3. Gluing Performance

Crowning Setting

Proper crowning helps ensure uniform pressure and glue application. Insufficient or uneven crowning may lead to poor glue transfer, delamination, or bubble issues, reducing bonding strength between layers.

Surface Cleanliness

Contamination such as paper dust, glue residue, or debris on the roll surface can interrupt gluing and cause uneven adhesive application, leading to weak bonding performance.

4. Board Flatness and Stability

Roll Parallelism

Incorrect roll parallelism leads to poor edge forming, skewed board edges, and warping, all of which affect dimensional accuracy and overall flatness.

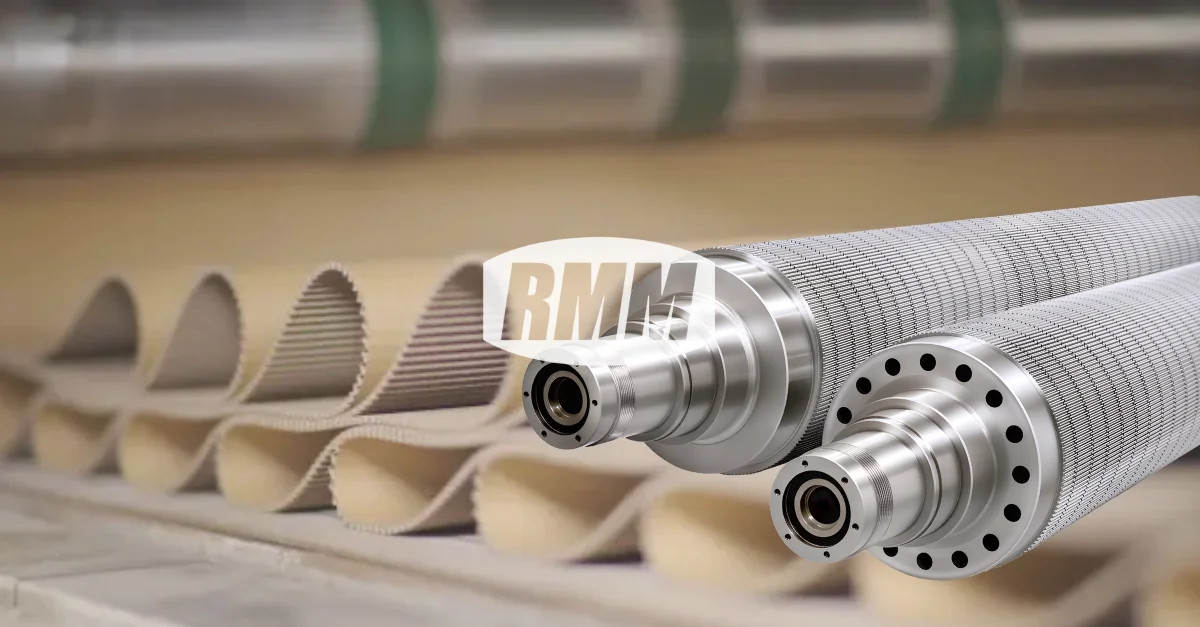

Roll Rigidity

Larger roll diameters provide better rigidity and more stable operation. Insufficient rigidity may cause deformation or vibration during production, affecting flute forming and final board performance.

As a professional corrugating roll supplier, RMM Corrugating Rolls stand out for their superior manufacturing and durability. With precise tooth profiles, wear-resistant materials, and excellent rigidity, RMM rolls ensure long-lasting flute consistency, efficient and uniform forming, and precise glue application. They significantly enhance overall board quality, reduce waste, and are the ideal choice for high-efficiency, high-quality production.