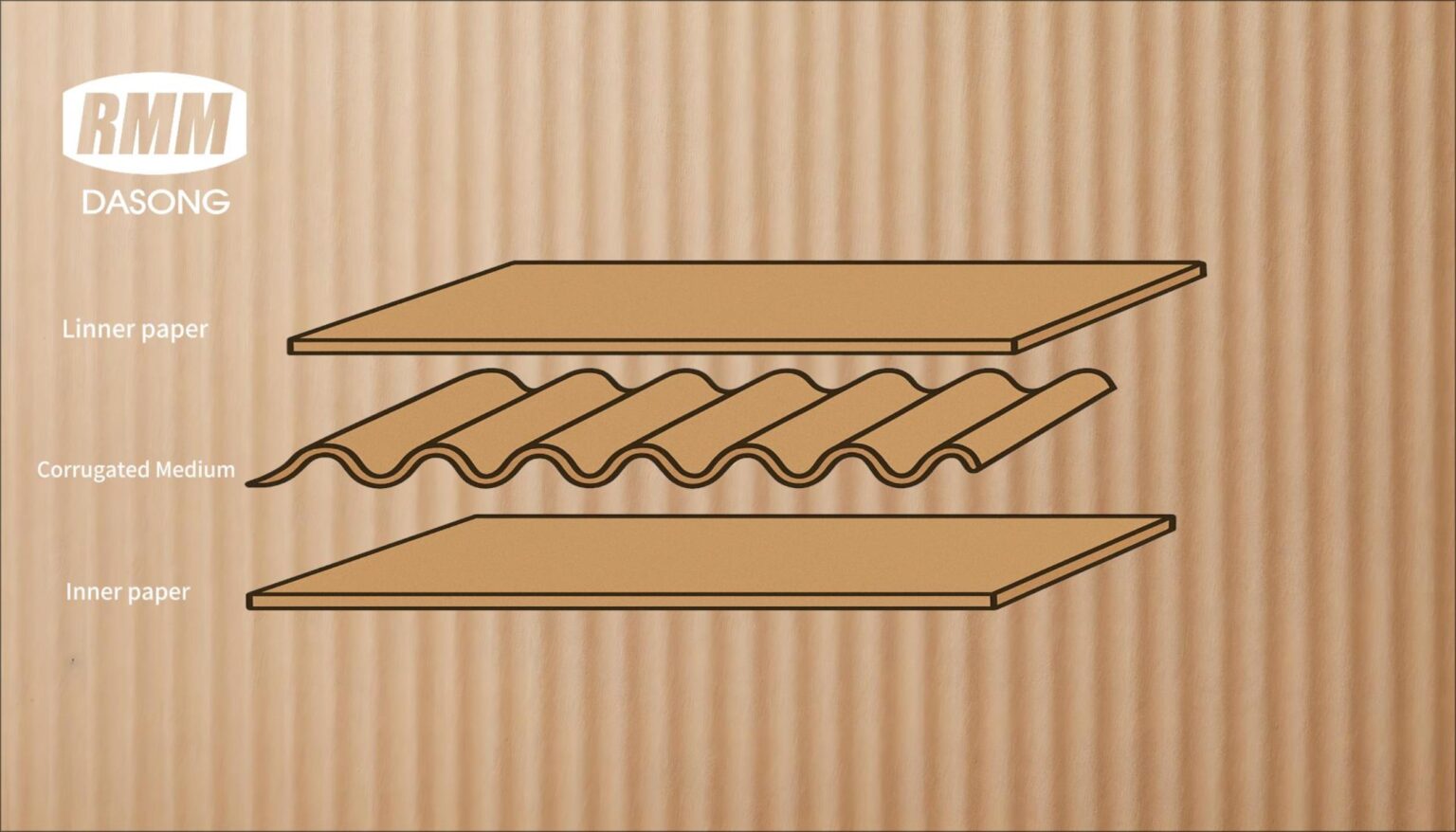

Corrugated rollers are essential components in the production of corrugated board. However, deformation during operation remains a common challenge that can impact product quality and production efficiency. Understanding the root causes is crucial for prevention.

Material and Manufacturing Defects

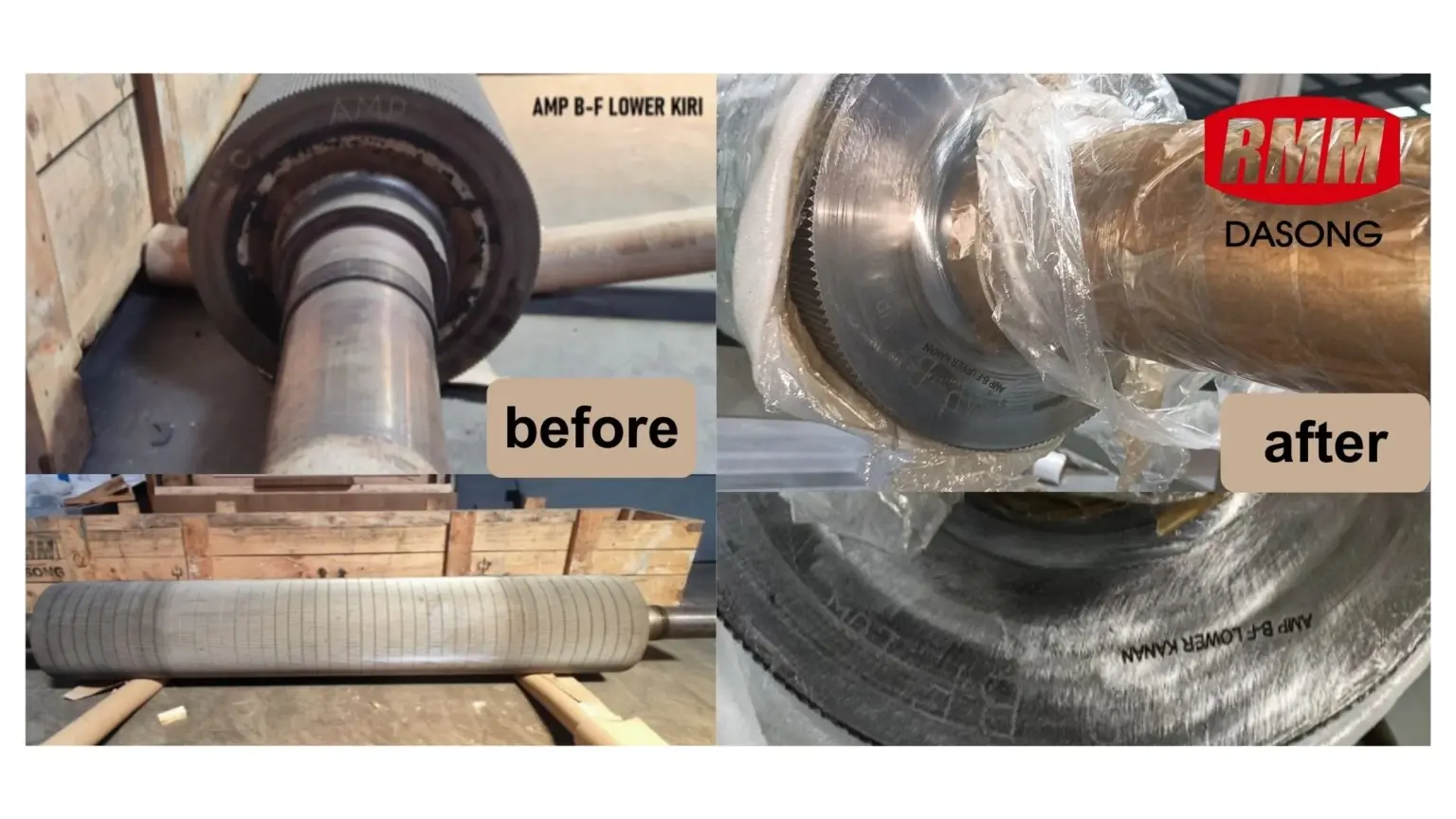

The quality of steel used in rollers significantly influences their durability. Inferior materials containing impurities or uneven alloy distribution are more prone to deformation. Additionally, manufacturing flaws—such as inadequate heat treatment, uneven cooling during casting, or imprecise machining—can create internal stresses. These unresolved stresses may gradually release during operation, leading to structural changes in the roller.At RMM, we exclusively use premium alloy steels with optimal hardness and purity to form the foundation of our rollers.

Operational and Maintenance Issues

Improper use is one of the main causes of premature roller failure. Excessive or uneven pressure—especially during the bonding process in single facers—can gradually distort the roller. In addition, continuous wear caused by abrasive mineral particles in the paper further weakens the roll tips and undermines structural integrity. When regular cleaning and inspection are neglected, this wear accelerates, greatly increasing the likelihood of deformation.To combat this, RMM designs rollers for exceptional wear resistance and provides comprehensive maintenance guidelines to ensure optimal performance.

Design and Environmental Factors

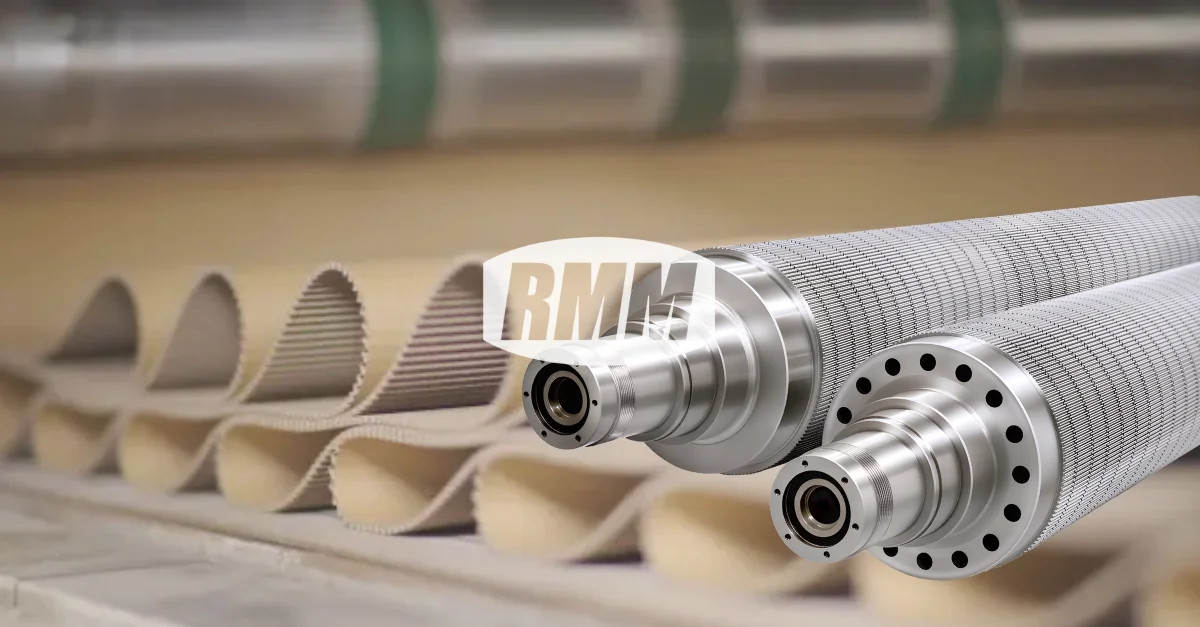

A roller’s design determines its inherent strength. Inadequate wall thickness or insufficient support can make it vulnerable to bending under load. Similarly, selecting an unsuitable tooth profile for specific production demands may lead to uneven stress and deformation.

Environmental conditions also contribute. High temperatures, humidity, or exposure to corrosive chemicals can cause material expansion or surface corrosion, further compromising the roller’s integrity.

With 30 years of industry experience, RMM possesses an extensive database of flute profiles, enabling us to select and engineer the optimal tooth design for your specific application and pressure conditions.

Conclusion

Corrugated roller deformation stems from multiple sources—material quality, manufacturing precision, operational practices, design suitability, and workplace environment. A proactive approach involving careful roller selection, standardized operation, and consistent maintenance is essential to minimize deformation and extend service life.