In the modern packaging industry, the corrugated cardboard production line is like the blood vessels that supply life, and the single facer is the indispensable “heart” of this production line. Through precise operation, it transforms seemingly ordinary corrugated base paper into corrugated cardboard with structural strength, providing reliable protection for countless goods during transportation.

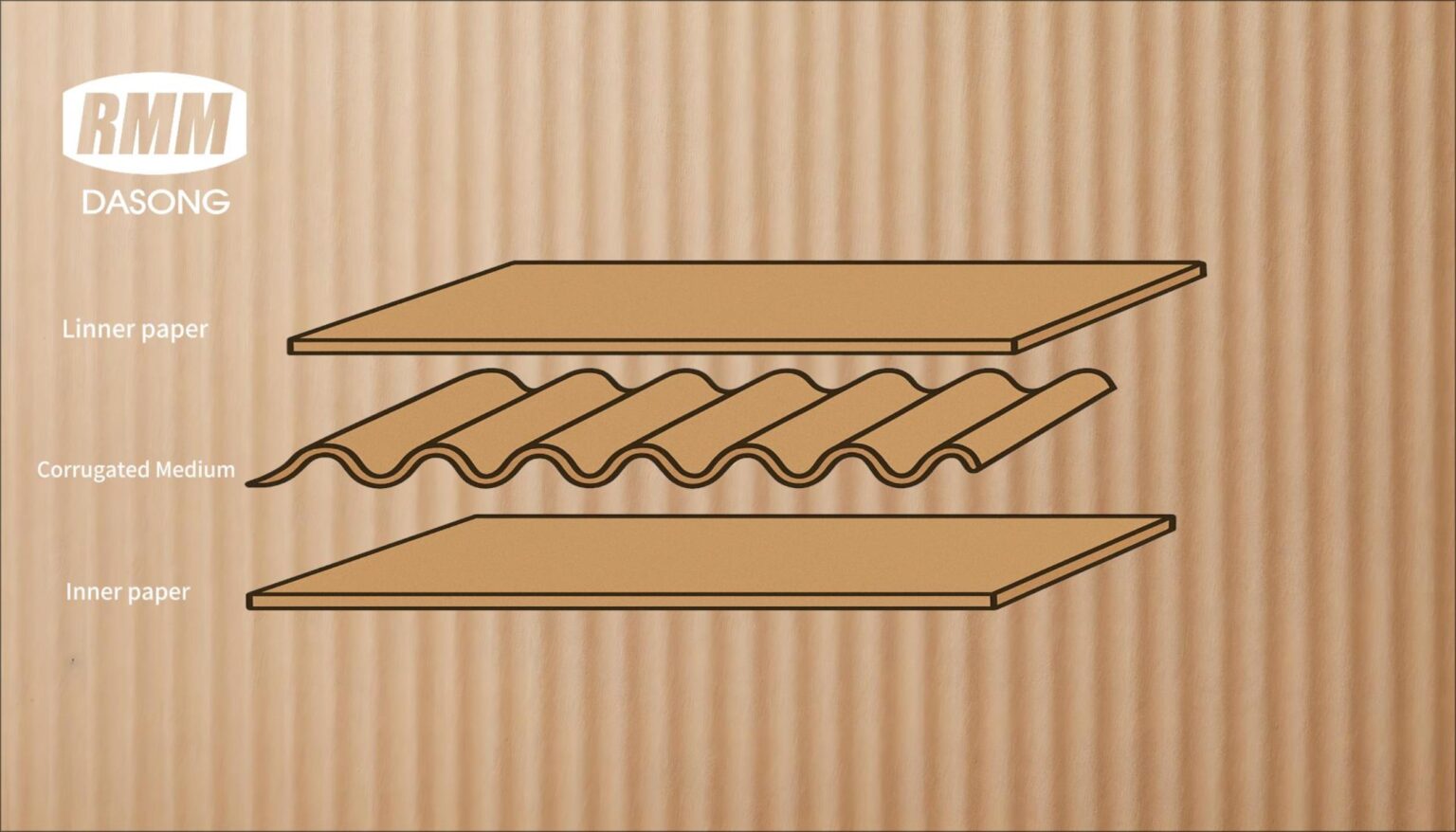

The working principle of a single-facer is simple and efficient: the corrugated base paper is pressed into a wavy corrugated paper by a pair of precisely matched corrugated rollers; after evenly applying adhesive, the face paper and corrugated paper are firmly bonded together to form single-faced corrugated board.

Although this process is not complex, it has a significant impact on the quality of the final product. Modern single-facer corrugators are equipped with advanced technology that ensures even adhesive application, optimal pressing conditions, and precise temperature control. This technological advancement improves product quality, thereby reducing returns and increasing customer satisfaction.

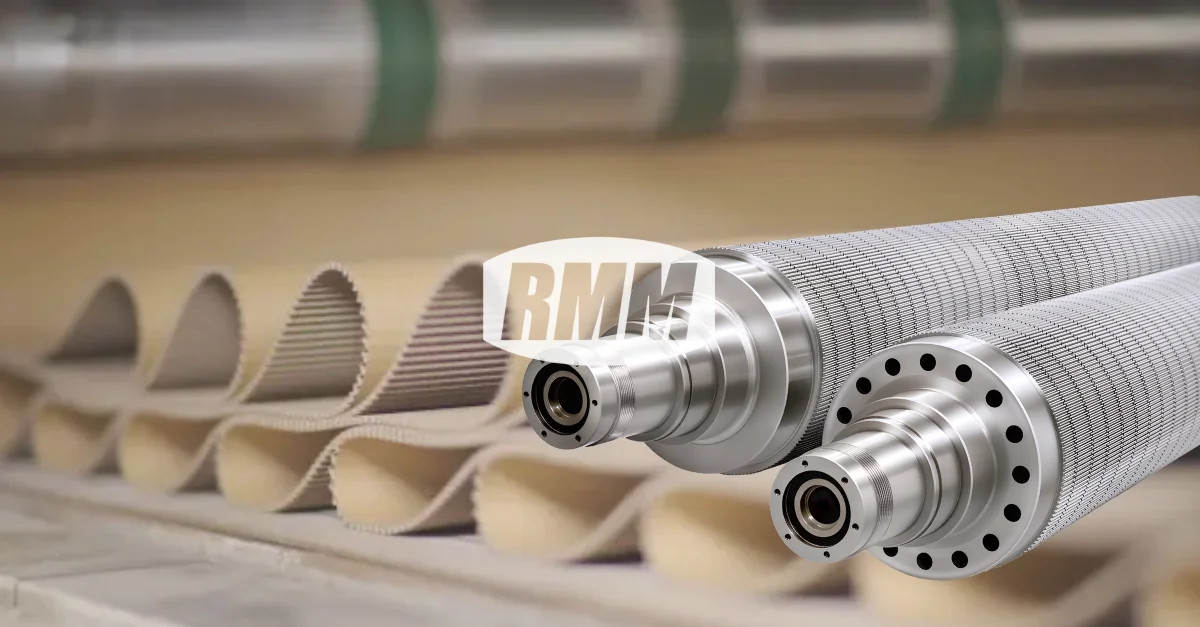

Inside a single-facer, the corrugating rollers play a crucial role. The height and shape of each flute must be consistent; this is the foundation for the subsequent double-face lamination process to produce high-quality cardboard. Moreover, by using corrugating rolls with different flute profiles, the single facer can produce corrugated boards with varying performance characteristics—whether the goal is higher strength, better cushioning, improved stacking performance, or optimized material usage.

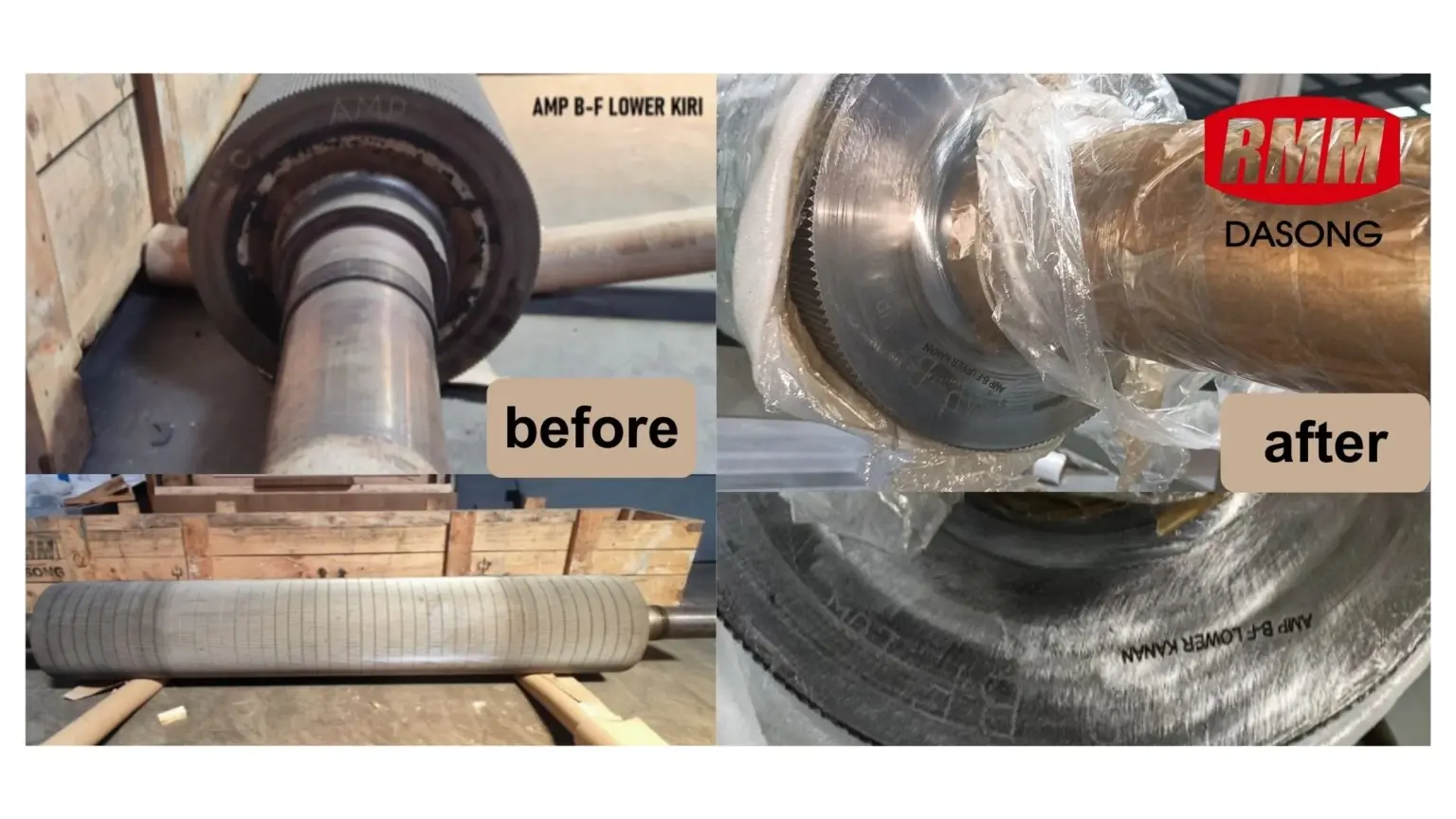

We believe that an excellent single facer should not merely be able to “operate,” but should maintain stability and precision throughout the high-intensity production process day after day. This is precisely the value of high-quality corrugating rolls—their precision directly determines the flatness, bonding strength, and overall efficiency of the corrugated board. Just as the heart needs to be healthy to sustain life, a singlefacer needs high-quality corrugating rolls to perform at its best. RMM’s corrugating rolls are engineered to deliver this reliability, ensuring consistent flute formation and long-term stability in demanding production environments.

As the packaging industry continues to evolve, single facers will continue to play a core driving role, propelling the entire industry towards a more efficient and sustainable future.