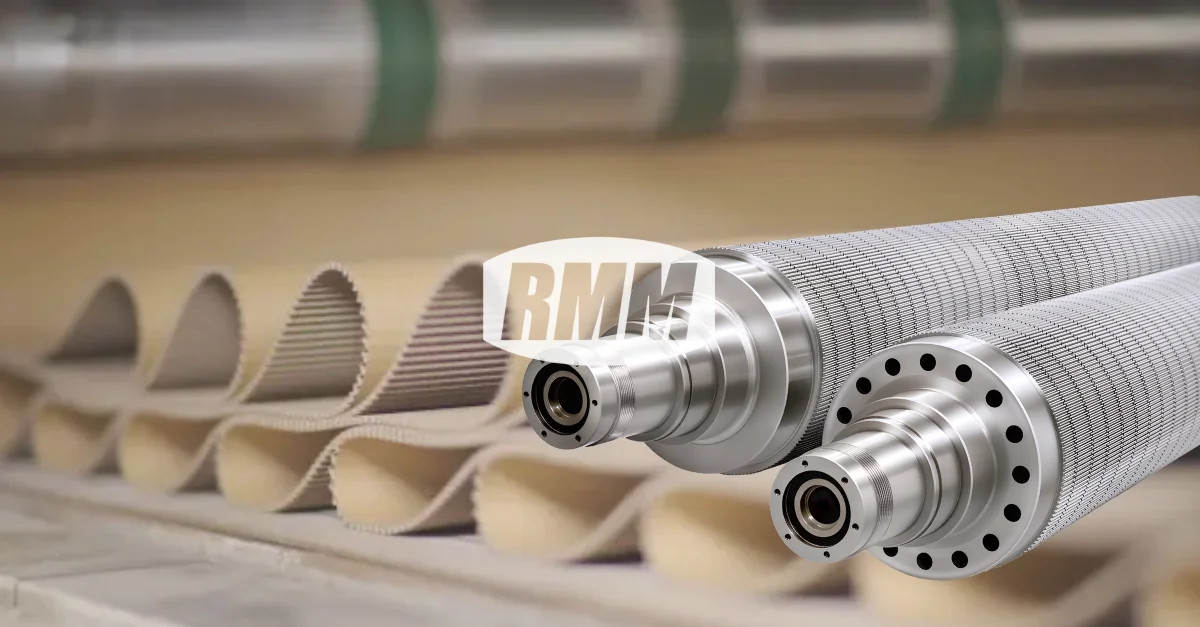

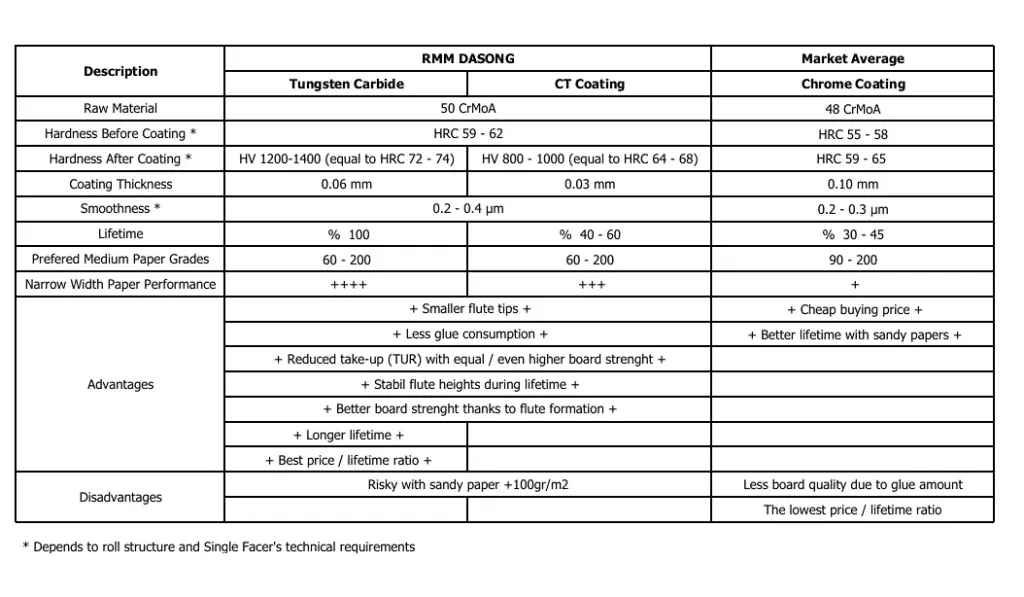

In the production of corrugated rolls and corrugated paper rolls, tungsten carbide corrugating rolls play a crucial role in improving production efficiency and board quality. They are essential components in single face corrugated and corrugated board roll manufacturing lines, delivering durability and precision far beyond traditional chrome-coated rolls.

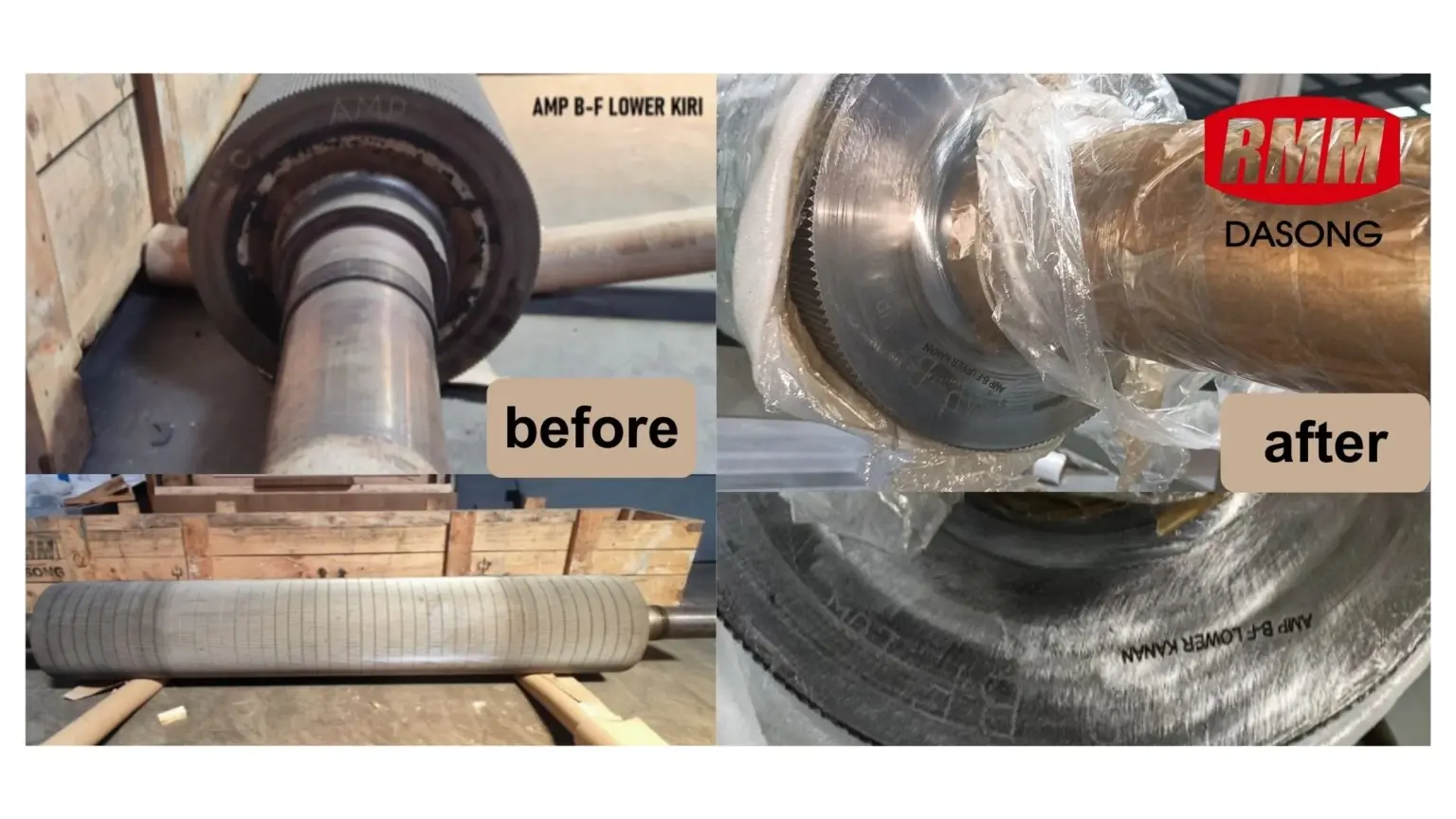

Extended Lifespan and Wear Resistance

Tungsten carbide corrugating rolls typically last 3–5 times longer than chrome-coated alternatives. Their outstanding wear resistance—only 0.06–0.08 mm of total flute height wear—keeps the corrugated board rolls stable and consistent throughout extended production cycles.

Precision for Quality Corrugated Packaging

Minimal wear ensures the accuracy of flute profiles, maintaining stable board thickness and surface quality. This precision directly impacts corrugated packaging rolls, helping manufacturers produce consistent, high-strength packaging materials with excellent flatness and bonding performance.

Reduced Maintenance, Enhanced Efficiency

With fewer replacements and longer maintenance intervals, downtime and labor costs are minimized. Despite a higher initial investment, the overall cost of ownership for tungsten carbide corrugating rolls is significantly lower in the long run due to reduced maintenance and downtime.

Sustainability and Reliability in Corrugated Production

The long lifespan of tungsten carbide corrugating rolls reduces waste, energy use, and transport frequency—making them an eco-friendly solution for the corrugated packaging industry. Whether producing single face corrugated or double-wall boards, these rolls support sustainable, efficient, and reliable manufacturing of corrugated paper rolls and corrugated board rolls.